BLOG

-

How To Make Health, Safety And clean Medical Device

When it comes to medical equipment, cleanliness, safety, is critical. All medical devices, whether disposable, implantable or reusable, must be cleaned during the manufacturing process to remove oil, grease, fingerprints and other manufacturing contaminants. Reusable pro...Read more -

The Art Of Metal Engraving

Engraving, like sculpture, has a long and fascinating history that spans various cultures and time periods. Engraving is the practice of incising a design onto a hard, flat surface, often for the purpose of creating prints or reproductions. The history of engraving can b...Read more -

Exploring the Future of CNC Router Technology: Innovations and Trends to Watch

What is a CNC Router? CNC milling machines are automated machine tools that are widely used for cutting 2D and shallow 3D profiles from generally soft materials. CNC milling machines use three axes of motion to transport rotating tools to remove material in pr...Read more -

Metal or Plastic: What Are the Differences?

When it comes to creating a product, the choice between plastic and metal can be a difficult one. Both materials have their unique advantages, but they also share some surprising similarities. For instance, both plastic and metal can offer heat resistance and strength, w...Read more -

Metal Stamping Process Standards

Metal stamping is a manufacturing process in which metal is placed into a specific shape in a machine. It is mainly used for metals such as sheets and coils, and is suitable for producing high-precision products.Stamping encompasses multiple forming techniques such as bl...Read more -

Professional Medical device manufacturer- RuiCheng

Overview Part's safety and accuracy are critical to the medical industry.As a professional Medical device manufacture, RuiCheng can provide durable and medical-grade plastic injection molding parts, at the same time our parts can satisfy product specifications...Read more -

Die Casting:Definition,Materials,Benefits and Applications

As a common metal casting process, die casting can create high-quality, durable parts and exact dimensions.Because of it’s particularity. Die casting can meet customers’ complex customization needs. This article will introduce to you about die casting’s four characters. ...Read more -

Stamping Processing Mold Customized

As one of the traditional processes, stamping is very popular in the customization industry. Especially for manufacturers, the stamping process can bring huge benefits. If you want to know how this is achieved, please continue reading this article. ...Read more -

Things That Make Precision Metals Precise

Precision metal refers to metal materials that exhibit a high level of accuracy in terms of dimensions, composition, and material properties. It encompasses various important considerations for your product or man...Read more -

Commonly used surface treatment methods for metals

1.Coating Treatment: One of the common surface treatment methods for hardware is coating treatment, such as galvanizing, nickel plating, and chroming. Coatings provide a protective layer on the metal surface, enhancing its corrosion resistance and improving the appearanc...Read more -

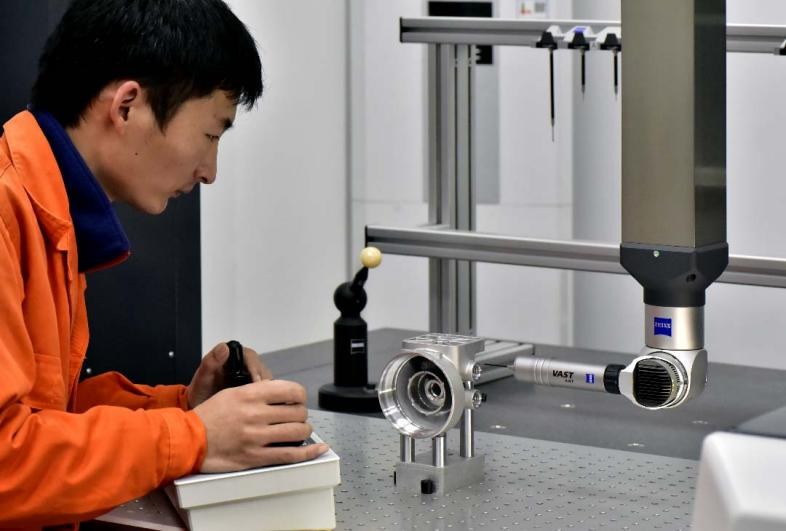

Ensuring Quality Compliance of Metal Parts Quality Control Practices at Xiamen Ruicheng

The purpose of quality control is not only to prevent defects, but also to ensure that parts are manufactured according to design specifications and operate properly. A good quality control program helps keep production on time and on budget, and also helps avoid product...Read more -

What is stamping?

Stamping is a manufacturing process used to shape or form metal sheets or strips by applying force through a die or a series of dies. It involves the use of a press, which applies pressure to the metal material, causing it to deform and take on the shape of the die. ...Read more